The MaeserKompressor is a refrigerant compressor with a superior degree of performance. It is employed where efficiency counts.

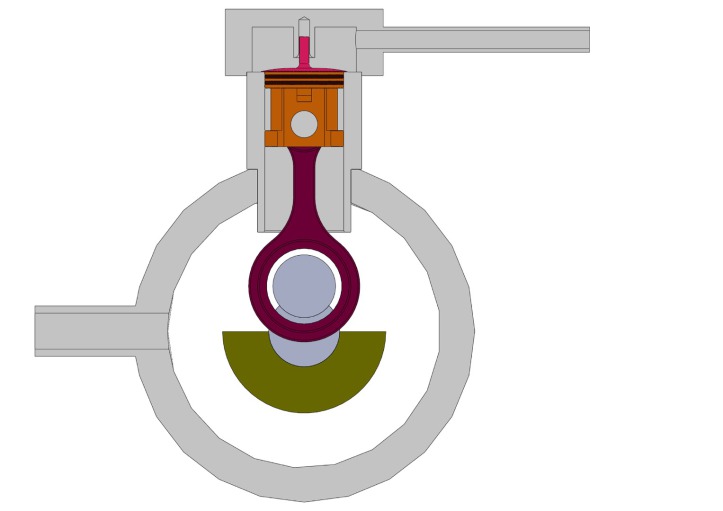

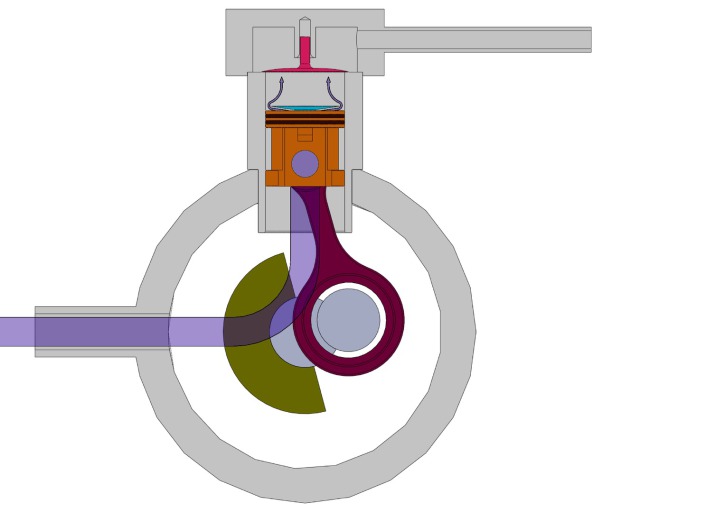

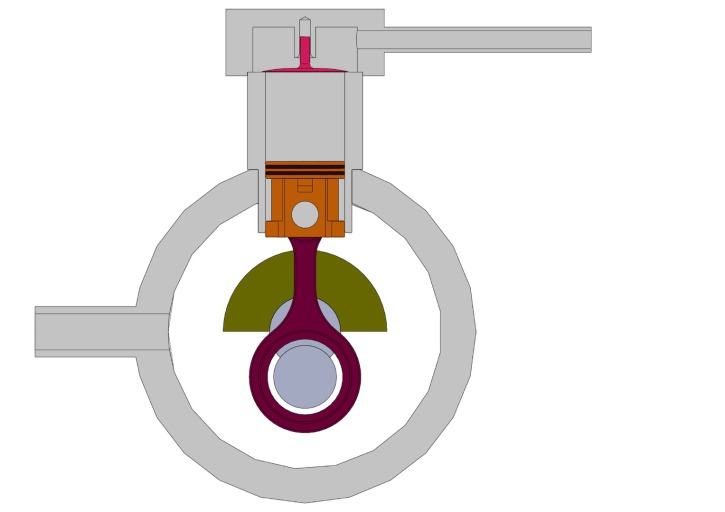

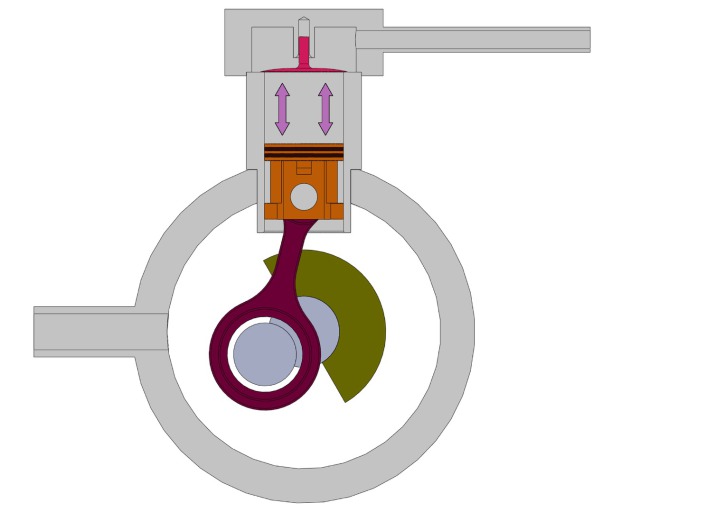

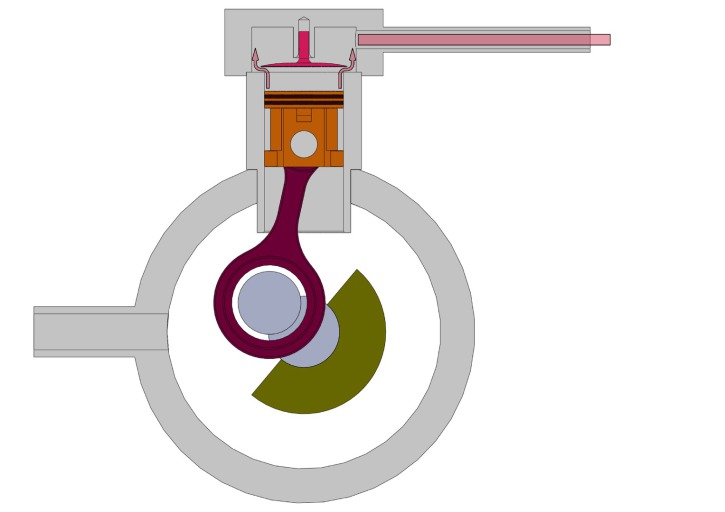

It is a reciprocating compressor. The inlet valve is incorporated in the piston and the outlet valve acts as the cylinder head. The intaken gas flows from the crankcase through the piston into the cylinder where it is compressed.

Compared to the state of art, power consumption can be reduced from 15% to 25% depending on the execution of the compressor.

Performance results measured on prototype "Compressor No. 3

As a matter of fact the plot rate of the MaeserKompressor is high and stays comparatively even over the pressure ratio. Accordingly there is also a big improvement in the efficiency. The reason for that are the following design features.

Inlet and Outlet Valves

Compared to existing reciprocating compressors the available space for incoporating the valves is twice as much since the inlet valve moves from the cylinder head into the piston. This is of advantage for 4 reasons.

- The dead volume is eliminated. The piston can even touch the outlet valve.

- Huge valve diameters allow good opening aperture dimension to reduce flow losses

when charging and discharging the cylinder.

- There is continous movement of the valves, no flittering as it is the case on reed valves

used nowadays.

- The compressor is no subject to liquid strokes anymore since outlet valve moves

elastically away if liquid is captured in the compression chamber.

The concentric design of the valves enables equal stress distribution. They are made of titanium alloy. This material offers high tensile strength combined with high elasticity and low specific weight in order to dampen the valve impact. The strength is well below fatigue limit and guarantees long service life of the valves.

Piston and Cylinder

Piston and cylinder are made of cast iron. This allows precise fit of cylinder and piston which is of advantage for reducing gas leakage and enables smooth running conditions and low wear. On top of that there is a perfect valve seat for both inlet- and outlet valve.

Roller bearings

The crankshaft and piston rod is running on roller bearings. This contributes to approx. 3 % in efficiency increase. Additionally, the requirements for oiling are low since roller bearings can run on an oil film only. This helps to keep the compressor design simple and the production costs inexpensive.

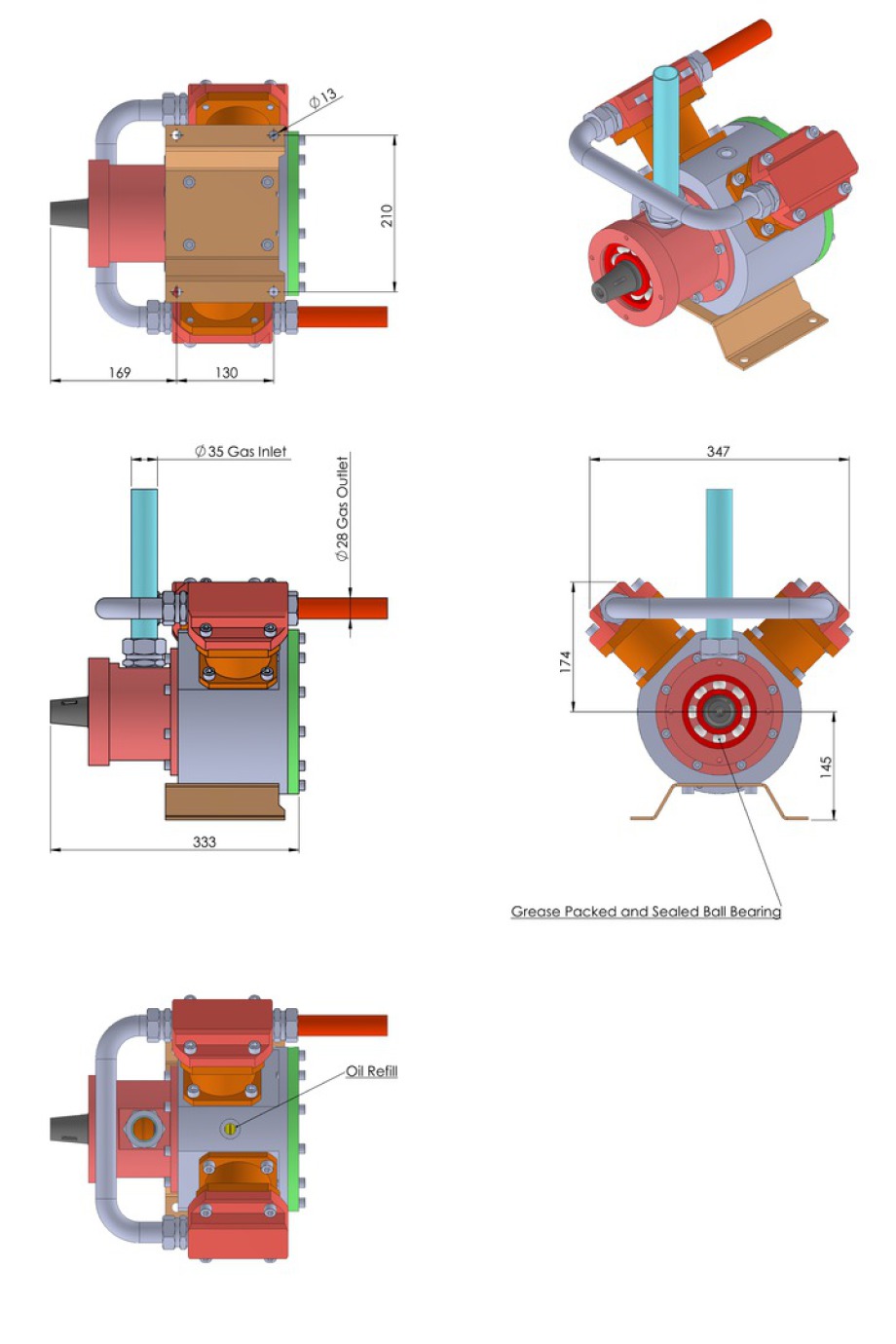

Bus Compressor Type 2MRC 470-B

Bus Compressor Type 2MRC 470-B

- Refrigerant R134 a

- Swept Volume = 470 cm3

- Cooling capacity = 20 kW, COP = 3.6 (State of Art =3)

@ tc = 50° C, te = 0° C, Liquid Subcooling = 0 K, Gas Superheat = 20 K, Speed=1450 rpm

- Minimum Evaporating Temperature = -15°C

- Maximium Condensing Temperature = 80°C

- Weight (without Magnetic Clutch) = 21 kg (State of Art = 33 kg)

- Oil Charge = 0.5 l

- Maximum Speed = 4000 rpm

- Mechanical seal positioned between bearings, not overhung design. Smooth running conditions for seal, no influence from drive belt tensioning. Therefore low leakage rate, long service life and no subject to

complaints of seal anymore

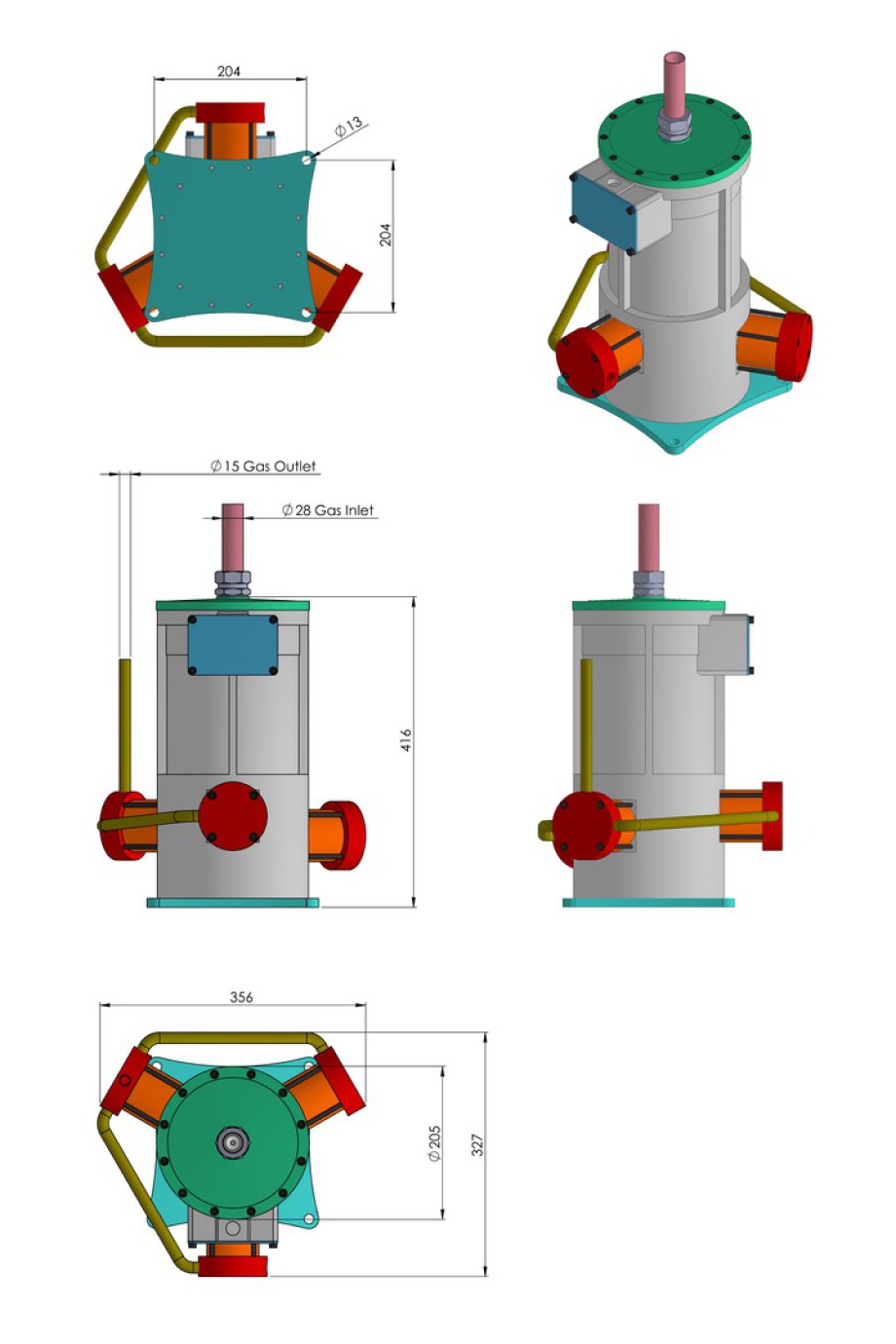

Semi hermetic Compressor Type 3MRC 228

- Refrigerant R134 a

- Swept Volume = 228 cm3

- Cooling capacity = 7.6 kW, COP = 2.74 (State of Art = 2.39)

@ tc = 48.9° C, te = -6.7° C, Liquid Subcooling = 0 K, Gas Superheat = 18.3 K

- 3 kW 4-Pole Asynchronous Motor IE3

- Oil Charge = 1l

- Speed = 1450 rpm

Semi hermetic Compressor Type 3MRC 174-PM

This compressor is driven by a permanent magnet synchronous motor from Leroy Somer and speed controlled. The efficiency is outstanding. It is 33% over state of art. Therefore savings in electrical energy are 25%.

- same dimensional drawing as 3MRC 228

- Refrigerant R134 a

- Swept Volume = 174 cm3

- Cooling capacity = 10.6 kW, COP = 2.93 (State of Art = 2.2)

@ tc = 48.9° C, te = -6.7° C, Liquid Subcooling = 0 K, Gas Superheat = 18.3 K, speed = 2750 rpm (half

speed)

- Dyneo Motor from Leroy Somer, Type: LSRPM 90

- Oil Charge = 1l

- Speed Range = 500 rpm - 5500 rpm